North American railway company BNSF Railway has recently announced that it is currently implementing immersive technology into its mechanical training programs to keep workers safe, utilizing virtual, augmented, and mixed reality (VR/AR/MR) to enhance safety strategies and improve role readiness amongst the mechanical workforce.

BNSF claimed that, in collaboration with its VR Learning Solutions provider,Roundtable Learning, the ongoing testing of the training simulations aims to tackle specific scenarios of risk, enabling workers to prevent possible incidents and injuries during their work.

The VR training programs complement BNSF’s existing instructor-led mechanical programs by reinforcing learning techniques that cannot be replicated in traditional training modalities. Built for in-depth exposure to step-by-step processes, the VR program provides experiential learning opportunities for mechanical employees to build their knowledge of the importance of personal protection equipment (PPE), improve risk awareness, and hone other procedures. Each time employees encounter safety hazards within the VR experience, warnings alert learners to pressurized systems and reinforce safe lifting practices.

Christopher Skinner, the manager responsible for locomotive mechanics at BNSF, stated that the use of VR training in the mechanical field was mainly motivated by the desire for consistency. By employing a standardized approach to training, there is better control over the delivery of instruction. Unlike instructor-led training, where the message can differ depending on the instructor and location, VR training ensures that mechanical students receive identical and accurate information throughout the company.

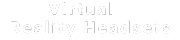

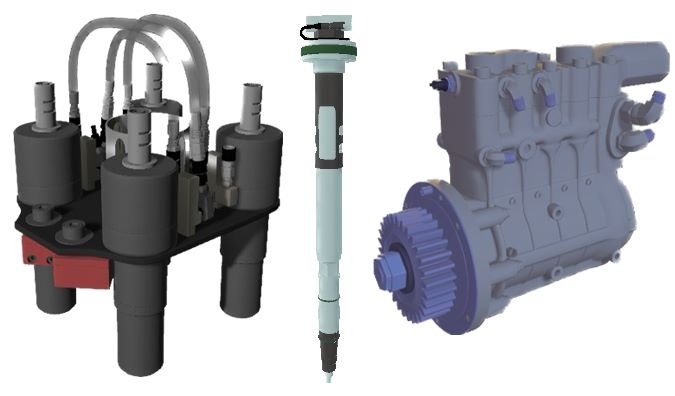

BNSF explained the need to create precise 3D models with appropriate levels of detail for their immersive training. This involved creating digital representations of locomotives, the workshop environment, and specific components and tools. At times, experts from the BNSF Technical Training Center had to create digital counterparts for tools or parts that did not already exist.

“We had to adopt a reverse-engineering approach in order to manufacture the necessary components for the locomotive,” Skinner further explained. “We would acquire the physical component and capture multiple images from various angles, using a tape measure or ruler for accurate measurement. Based on this data, a digital component was generated.”

In the provided training video by BNSF, a trainee can be seen using an HTC VIVE Pro VR headset and HaptX Gloves DK2. This setup allows trainees to have a more immersive experience with haptic feedback from the gloves while interacting with virtual objects.

Jeff Suchan of Roundtable Learning commended BNSF for their innovative approach in utilizing virtual reality (VR) training programs. Suchan stated that by implementing this strategy, BNSF has not only transformed the way employees learn and train but has also contributed to the development of safer practices in the rail industry.

According to Mark Stockman, BNSF’s director of mechanical training, the company closed out last year with the lowest injury frequency rate in its 175-year history. This latest VR training initiative is therefore aimed at keeping BNSF’s commitment for safety front and center, whilst simultaneously upholding the company’s standards of innovation.

BNSF stated that it remains committed to investing in innovative technologies like VR simulations to improve its mechanical training programs. These technologies play a crucial role in integrating frontline work with digital advancements, aligning with the company’s goal of creating a safe and injury-free workplace. Furthermore, BNSF mentioned its plans to gradually expand the selection of VR coursework, providing trainees with access to a diverse range of departments and crafts.